Metal Terminal Box Band Heater

shengfumei mica band heaters are efficient and economical solutions to the indirect heating applications at medium temperature up to300- 480°C. Mica Bands are commonly used in Plastics Injection Molding, Extrusion, Blow Molding applications as well as in Commercial Cooking, Dies and Electric Motors

- SFM

- CHINA

- 2-7Day

- Information

- Download

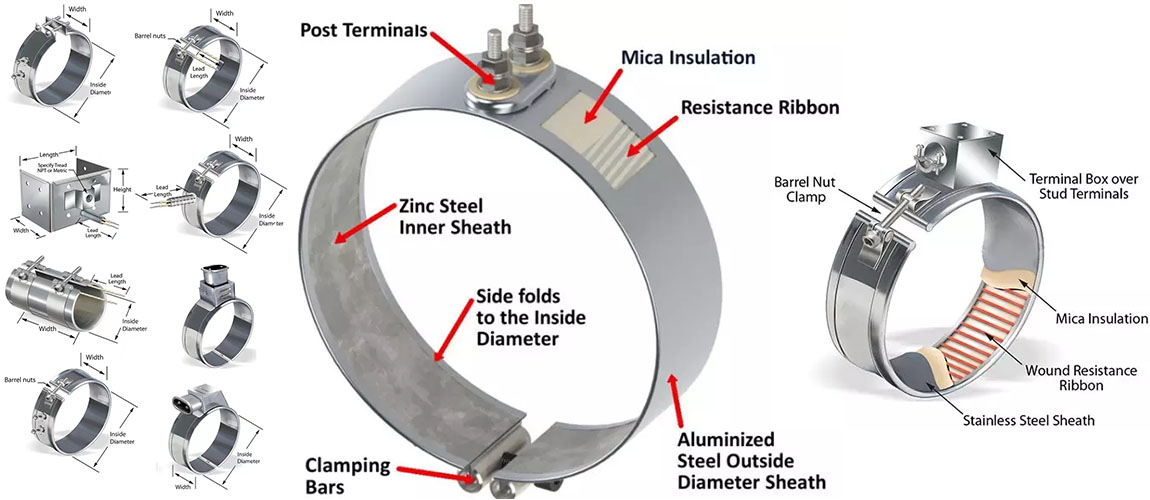

MICA BAND HEATER

shengfumei mica band heaters are constructed by winding a nickel-chrome resistance ribbon around mica insulation and encapsulated in a stainless steel sheath. With temperature capabilities of up to 480°C, these heaters are ideal for plastic processing applications and for anywhere heat is needed on a round or curved surface.

CERAMIC BAND HEATER

Ceramic band heaters are designed with spirally wound inner resistance coils evenly threaded through interlocking insulated ceramic "tiles". The ceramic core of tiles is housed beneath a stainless steel sheet with serrated edges. Typical applications are plastic molding, extrusion and molding presses.

NON-STANDARD LOCATION OF LEADS OR TERMINALS

Terminations could be offset, paralleled, centered, or at each end. Lead wires are available.

Leads or terminals may be located at any reasonable place along the heater for applications where standard connections may be inaccessible.

HOLES AND CUTOUTS

Mounting holes locations could be customized. Please provide drawing for hole dimensions and locations.

ONE PIECE OR TWO PIECE CONSTRUCTION

2 Piece construction is very suitable for locations where 1 piece is difficult to be installed.

2 Piece construction is available with any termination or clamping styles.

Technical parameters | |

Voltage | 110V/220V/230V/240V/380V/415V |

Power | Customized |

Cold Withstand Voltage | AV2000V/ 0.75mA/ 3s |

Hot Leakage Current | ≤2mA |

Wattage Tolerance | +5%, -10% |

Max. Watt Density | 3.5W/cm² (Standard 3W/cm²) |

Resistance Tolerance | +10%, -5% |

Max. Temperature | 480℃ - Mica 600℃ - Ceramic |

Main Materials | |

Sheath | Stainless steel 430 / 201 / 304 / |

Resistance Wire | Ni80Cr20 |

Insulation | Mica/Ceramic |

Lead Wire | Fiberglass (steel protective sleeve, steel hose & braid are available) |

Terminal | Thread, ceramic, metal box, plug |

Features Design Details

1. Energy efficient, less power consumption Please provide the following information:

2. Provide uniform heat distribution 1. Operating temperature

3. Thermally insulated 2. Heated medium

4. Uniform temperature 3. Voltage and phase

5. Easy to install and remove 4. Rating power

6. Highly flexible 5. Termination types

7. Long service life 6. Mounting method

7. Detail dimensions or drawing

8. Holes and cutouts' position

Note:The more details provided, the better it'll be designed and fits the application