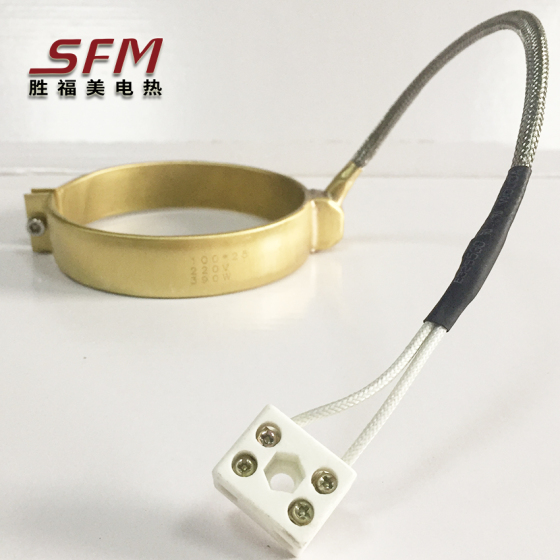

Surface Leads Brass Nozzle Band Heater

Brass nozzle band heaters are completely against external agents such as melted plastics. They are very resistant to wearing and shocks. High watt-density per square centimeter allows a fast and safe reaching of required working temperature. Brass nozzle heaters are submitted to extremely high pressure that ensure high insulation, excellent thermal exchange, lack of internal voids, perfectly smooth contact area for an optimum and uniform heat transfer to every part of the nozzle. Characteristics Sealed band heater in brass, with folded ends Band heater connection, waterproof technology Electric insulation by mica plate Connection: nickel core, fiberglass insulated + earth wire; protected by a galvanized steel braid Max. watt density : 5 W/cm² (Wattage tolerance: +5% -10%) Diameter: 25 to 150mm Height: 25 to 70mm Max. operating temperature over the surface of the heater: 340ºC, depending on working conditions. Brass sealed nozzle heaters can be supplied with a built-in J-type thermocouple.

- SFM

- CHINA

- 2-7 DAY

- Information

BRASS BAND HEATER

Wrap around the nickel chromium resistance band on the Yunmu insulation layer and packaged in the brass condom,are normally used in plastic processing factories, for example extrution and injection machines.

Applications

Typical application such as blow molding machines, drum heating, extrusion die, plastic injection molding machines, vending machines, food service warming pots, food service warming pots etc

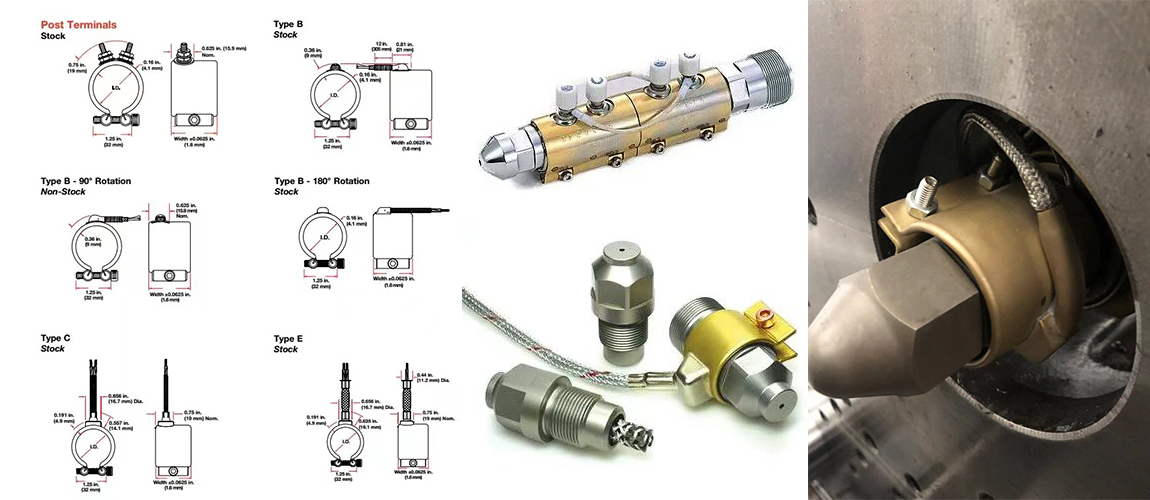

NON-STANDARD LOCATION OF LEADS OR TERMINALS

Terminations could be offset, paralleled, centered, or at each end. Lead wires are available.

Leads or terminals may be located at any reasonable place along the heater for applications where standard connections may be inaccessible.

HOLES AND CUTOUTS

Mounting holes locations could be customized. Please provide drawing for hole dimensions and locations.

ONE PIECE OR TWO PIECE CONSTRUCTION

2 Piece construction is very suitable for locations where 1 piece is difficult to be installed.

2 Piece construction is available with any termination or clamping styles.

Technical parameters | |

Voltage | 110V/220V/230V/240V/380V/415V |

Power | Customized |

Cold Withstand Voltage | AV2000V/ 0.75mA/ 3s |

Hot Leakage Current | ≤2mA |

Wattage Tolerance | +5%, -10% |

Max. Watt Density | 3.5W/cm² (Standard 3W/cm²) |

Resistance Tolerance | +10%, -5% |

Max. Temperature | 480℃ - Mica 480℃ - Brass 600℃ - Ceramic |

Main Materials | |

Sheath | Stainless steel 304 / Brass |

Resistance Wire | Ni80Cr20 |

Insulation | Mica/Ceramic |

Lead Wire | Fiberglass (steel protective sleeve, steel hose & braid are available) |

Terminal | Thread, ceramic, metal box, plug |

Features

Features

1. Energy efficient, less power consumption

2. Provide uniform heat distribution

3. Thermally insulated

4. Uniform temperature

5. Easy to install and remove

6. Highly flexible

7. Long service life

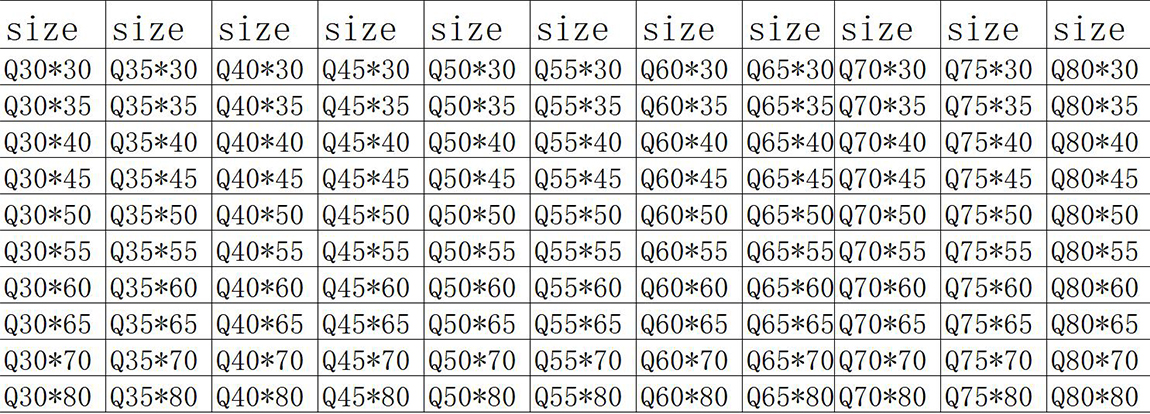

Design Details

Please provide the following information:

1. Operating temperature

2. Heated medium

3. Voltage and phase

4. Rating power

5. Termination types

6. Mounting method

7. Detail dimensions or drawing

8. Holes and cutouts' position

Note:The more details provided, the better it'll be designed and fits the application